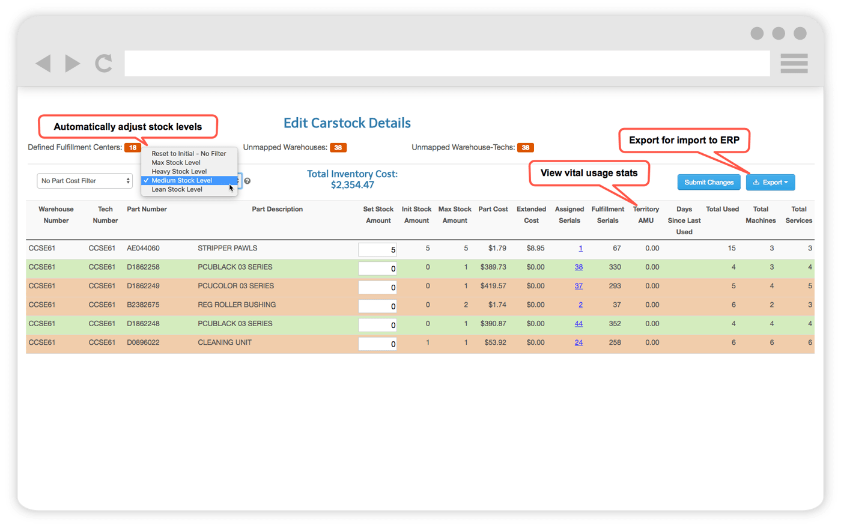

One of the most important aspects of any business is efficient inventory management. Not having enough inventory on hand means you run the risk of compromising service profitability due to the costs associated with return visits while having too much is costly in more ways than one. NEXERA’s Advanced Inventory Management solutions will help your company walk the inventory management tight rope, keeping your inventory logistics personnel informed when improper warehouse inventory levels are detected and when parts are falling into obsolescence. Accurate and automated car stock creation and inventory restocking functionality will also ensure that technicians have the right parts at the right time, increasing customer satisfaction and driving service profitability to new heights.

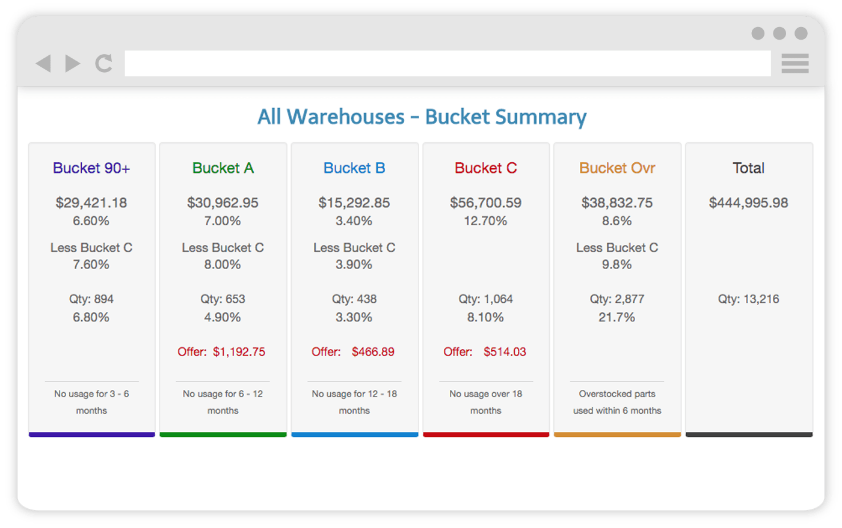

NEXERA’s process dealership data collected from the ERP system (e-Automate, OMD, NextGen, DDMS, plus many more) and identifies parts that may be overstocked or have not been used in defined time periods. This is reported in AIM to dealers as overstocked or obsolete parts. NEXERA then compares these parts against its WorldParts™ database to determine if these parts have usage by other dealers and a high probability of being sold. If it is determined that these parts have a high enough probability of being sold, parts offers can be viewed in AIM. When the offer is accepted, the parts are then sent to OPN’s parts facility for proving and clearing, then OPN will send the dealer a check for their obsolete parts. AIM also allows dealers to view up to date suggestions of parts available through the OPN to purchase based on actual company usage.

We help dealers, MSP/MPS providers and manufacturers identify and address inefficiencies, reduce costs, grow revenue, and increase profitability.

Copyright © 2024 NEXERA